abstract

The remote monitoring system of gas pipeline network is a computer-based production process control and dispatching automation system, which is used for on-site monitoring and automatic management. Remote monitoring mainly uses RTU as the terminal. At present, there are many forms, such as PSTN, laying special lines, radio stations, etc. In this paper, GPRS is used to realize the remote automatic monitoring system, which can collect the field data in real time, control the field locally or remotely, monitor the gas supply process comprehensively and in real time, and provide necessary reference data for production, dispatching and management, which can better meet the needs of urban gas pipe network monitoring.

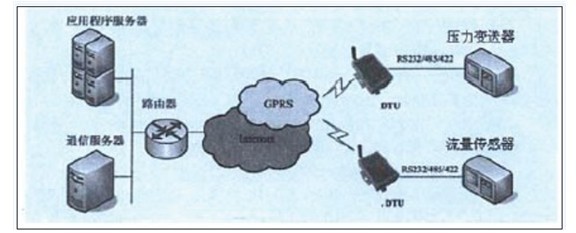

System composition

The system can remotely control the gas pipe pressure regulating station through the computer of the monitoring center. The data of field instruments can also be read through mobile terminal equipment, so that the production management personnel can master the change and flow of pipe tide pressure and dispose in time. The system composition is shown in Figure 1. It is composed of pressure transmitter, GPRS DTU, Internet network and management center computer.

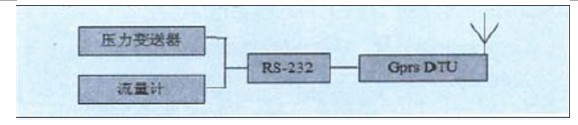

It is located at different pressure regulating stations to monitor the pressure and flow of the pipe network in real time. The pressure sensor is a bridge strain gauge. Under the action of pressure, the elastomer deforms, resulting in the change of the shape resistance of the strain gauge, so as to obtain an output linear with the deformation, and obtain 4 ~ 20mA signal output through amplifier amplification and transmitter circuit.

The hardware principle is shown in the figure. The pressure signal is directly connected to the GPRS DTU module of the wireless data transmission terminal through the RS232 interface to realize wireless transparent transmission. In this way, the on-site pressure signal is transmitted to the monitoring center database in real time through the Internet network.

The number of data acquisition points of gas pipeline network is large, which is required to meet the needs of data transmission in tuzan province. Because GPRS has real-time online characteristics, the system has no time delay and can synchronously receive and process the data of multiple data mining points without round inspection, it can meet the needs of data acquisition and transmission of sudden data in the remote monitoring system of gas pipe network.

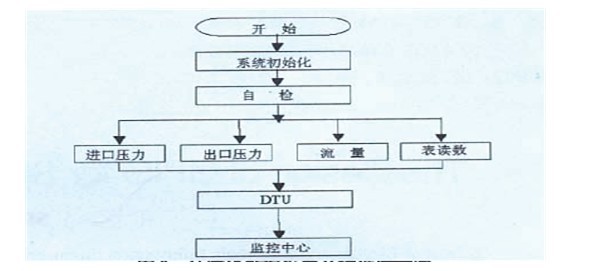

System software design

The system software is mainly composed of data acquisition module and data analysis module. The data acquisition module collects the data, sends the obtained pressure and flow signals to the GPRS wireless data transmission module through RS 232 interface, and transmits them to the monitoring center computer through intnet.

GPRS communication module DTU data transmission

GPRS adopts packet switching technology, which can occupy multiple wireless channels at the same time, and the same wireless channel can be shared by multiple users, so as to realize high-speed data transmission. Because GPRS supports the application based on standard data communication, it has the characteristics of full duplex operation, gap sending and receiving, always online, and only taking up system resources when sending and receiving data, so that the GPRS communication module can automatically attach to the GPRS network after startup, and establish a communication link with the monitoring center to send and receive the pressure, flow and other data collected on site at any time. The data transmission volume of the data acquisition point of the pressure regulating station is within 10kbps each time, and the GPRS network transmission rate can theoretically reach 171.2kbit/s. At present, the actual GPRS data transmission rate is about 40kbps, which can meet the requirements of the data transmission rate (≥ 10kbps) of the gas pipe network monitoring system.

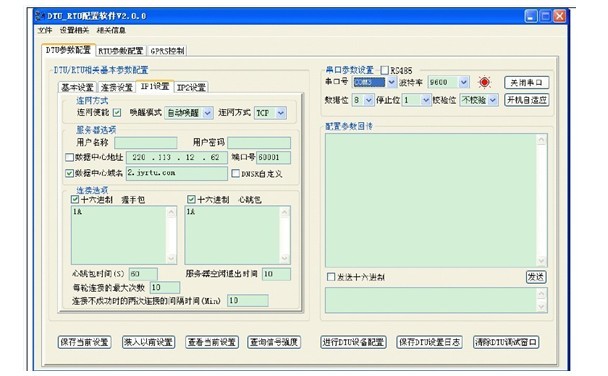

DTU, a terminal device for wireless data transmission using GPRS, supports PPP, TCP, UDP, ICMP and many other complex network protocols and socket standards, and has two modes: transparent data transmission and user free control transmission. At the same time, it supports various communication modes such as point-to-point, point to multipoint, equipment room, equipment and center. Using RS232 interface, you can send and receive wireless data and access the Internet anytime and anywhere.

The front-end and back-end DTU devices will analyze the data packets received from the front-end and the back-end DTU devices respectively, and will not analyze the data packets received from the front-end and the back-end DTU devices in the transparent data transmission mode.

When DTU is used as a server mode, DTU will always be in a listening waiting state to listen for connections initiated by remote clients. To establish communication, the remote client must know the IP address and listening port number of the server device. When DTU is used as the client mode, the DTU device wants to establish a connection with the server. The equipment connected to the DTU through the serial port first sends data to the serial port, and the DTU (in transparent transmission mode) receives {and caches these data. If the DTU does not establish a connection with the remote server, the DTU must first establish this connection. When the connection is established, the data can be transmitted in both directions between the client and the server. After accessing the network, DTU will establish a connection with the set data center according to the parameter settings, so as to realize data transmission.

monitoring center

The whole monitoring system consists of central upper computer system and lower computer system. The host computer system includes data acquisition and processing server. Workstations and databases. Among them, the data acquisition and processing server is mainly responsible for data exchange with the communication front-end computer, networking with the mobile company to obtain data, the central computer runs the background monitoring and analysis software of the monitoring system, and is responsible for data acquisition, analysis, report and other functions; The database server is used to store and manage the process data of the whole system. The task of the Xiang workstation is to provide a good man-machine interface for personnel to monitor and control. The lower computer system is composed of DTU unit.

The monitoring center has a fixed IP address and needs to maintain a real-time data connection with each data acquisition point of the gas pressure regulating station. After logging into the GSM network, the GPRS module will automatically connect to the monitoring center, report its IP address to the monitoring center, and maintain and maintain the link connection. The GPRS module detects the link connection. In case of abnormality, the GPRS module will automatically re-establish the link, The monitoring center and GPRS module DTU can conduct two-way communication with TCP / IP protocol through IP address to realize reliable data transmission.

Configuration software

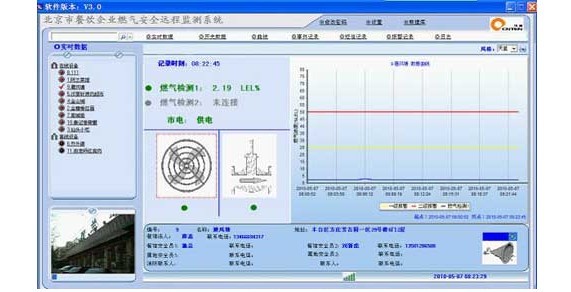

real-time display

1. The device list on the left shows the information of current online and offline devices. When the device is connected to the network, it will enter the "online device list" from the "offline device list". If the device is not online for a long time, it will enter the "offline device list" from the "online device list";

2. The upper left corner displays information such as gas concentration, power supply mode and whether the ventilation equipment is turned on;

3. The upper right corner displays the gas concentration curve in real time;

4. The lower side displays the equipment number, user name, contact person, telephone, fax, mobile phone, address, SIM card number and other information;

5. The middle text prompts the current equipment login time and the last time of collecting and returning data;

Historical records

Users can search history according to time period;

The history record will be drawn on the window in the form of curve, and the history record can be displayed under the window in the form of list. Through the history record, the equipment operation status and relevant trend can be viewed;

The history records queried at the same time can be exported to excel;

Concluding remarks

Through the research on the remote monitoring of gas pipe network based on GPRS, the data acquisition and analysis functions are realized, which is of great significance to gas management. When the voltage and current exceed the limit and the gas concentration exceeds the limit, the field controller sends an alarm message. According to the leakage concentration, the fan can be opened and the valve can be closed, and the system cost is low. It can be applied to the telemetry and remote control of gas pipe network to make it more safe and economical. Reliable operation and improving the automation level of gas supply management can save a lot of manpower and material resources.

销售王经理

销售王经理

微信公众号

微信公众号