introduction

SCADA system, i.e. data acquisition and monitoring system. It is a computer-based production process control and scheduling automation system. It can monitor and control the on-site operation equipment to realize various functions such as data acquisition, equipment control, measurement, parameter adjustment and various signal alarms. At present, SCADA system has a wide range of applications. It is mainly used in data acquisition, monitoring and control in power system, water supply and drainage system, petroleum, chemical industry and other fields.

At present, the basic structure of SCADA system is: intelligent monitoring equipment + data acquisition equipment + network system + user terminal. Among them, intelligent monitoring equipment mainly refers to measuring instruments or sensors, such as pressure gauge, liquid level gauge, flowmeter, etc. It can also be a valve that controls the flow of water. The network system is the line to realize the data transmission between the remote monitoring point and the SCADA control center. Data acquisition equipment is usually an independent data acquisition and control unit. Its function is to obtain equipment data from remote and field equipment, and transmit the data to the dispatching center of SCADA system through network system. It can also transmit the data or command of SCADA system dispatching center to field equipment.

At present, PLC (programmable logic controller) and RTU (remote terminal unit) mainly play this role. Compared with the traditional programmable controller PLC, RTU usually has excellent communication ability and larger storage capacity, and is more suitable for harsh temperature and humidity environment, providing more computing functions in line with proprietary standards. Due to the perfect function of RTU, RTU products have been widely used in SCADA system, which is more suitable for the needs of decentralized monitoring in modern emerging industries. The following case to be introduced is the SCADA system with remote measurement and control terminal RTU as the data acquisition equipment.

Case background

An enterprise is located in a mountainous area, which has the characteristics of large floor area, wide distribution of water source monitoring points, obvious topographic relief and so on. The water supply network is far away from the whole plant area. Water sources include production water, domestic water, sewage, etc., some of which are recycled water and some are non recycled water. The dispatching center needs to manage each water source pump station, pipe section and reservoir. Before using the SCADA system, the instrument is calibrated manually

And equipment for 24-hour monitoring, and regularly report data to the dispatching center by telephone, and then manually input the data into the computer for data analysis and report printing. When the remote equipment is abnormal, it will give an alarm manually and control the equipment on site.

The main purpose of establishing SCADA system is to solve the data acquisition and monitoring of water source monitoring points in branches and regions in the whole plant area. Through the monitoring and control of the remote field operation equipment, the data transmission of pipeline pressure, water flow, pool liquid level and valve opening status and the automatic control of valve switch are realized, so as to reduce the failure rate and improve the response time to the system, facilitate the timely and rapid understanding and control of remote pipelines and valves, and save human resources. At the same time, the data information of each water source monitoring point is transmitted to the monitoring center, which can also interface with the GIS system of the monitoring center to provide the data basis for the GIS system. Through the analysis of the transmitted data, the fault location can be found in time and the hidden trouble can be eliminated. So as to realize the informatization and modernization of production and domestic water management of the whole plant.

programme

At present, after years of construction by the telecommunications department, the GSM network has expanded its coverage and has become a mature, stable and reliable communication network, especially the GPRS data service of China Mobile. Moreover, using GRPS network to realize the wireless data transmission of pipe network monitoring points has the advantages of making full use of the existing network, shortening the construction cycle and reducing the construction cost, and the equipment installation is convenient and the maintenance is simple. In order to improve the efficiency of data transmission and the stability of the network, the data center is connected to the GPRS network of the mobile company through a 2m APN special line, that is, the project monitoring network and the data center form an APN special network, and all points adopt the fixed IP of the intranet. This network structure has been greatly improved in terms of real-time, security and stability.

Hardware equipment

According to the needs of users, the equipment to be monitored by the system mainly includes pressure, flow, liquid level and valves. Therefore, in the selection of RTU, the required 10 interface points include AI, Di and do. During the network layout, try to focus on multiple points and make full use of the interface resources of RTU, so as to save the cost of equipment purchase. At the same time, since the manufacturer is located in the north and a large number of monitoring points are distributed outdoors unattended for a long time, the temperature and humidity should be fully considered. Considering comprehensively, we selected jy-rtu6640, jy-md and multi-functional dam6640.

Both products have the characteristics of large data storage, convenient interface, strong scalability and more than 10 points. In particular, they all have a wide working temperature (- 40 ℃ ~ 85 ℃) and working humidity (5% - 95% RH), which can fully ensure the normal operation of the products in the outdoor low-temperature and humid environment in the north.

Jy-dam6640-s is an industrial field data acquisition module. It has RS232 / RS485 dual serial port. It supports 6 analog inputs, 4 optocoupler inputs and 6 relay control outputs. The communication protocol supports Modbus RTU / ASCII and user-defined protocols. It adopts industrial ARM7 processor and Embedded RTOS real-time operating system, which works stably and reliably. Easy to use, superior performance and flexible networking. The monitoring of the water tank is relatively complex. It is required to read the liquid level value. When the liquid level is higher than the warning value, it is necessary to give a remote alarm and automatically close the water inlet valve; On the contrary, when the liquid level is lower than the alarm value, it is necessary to give a remote alarm and remotely control the switch of the inlet and outlet valves according to the actual needs.

Jy-rtu6640 has RS232 / RS485 dual serial port; Dual server connection; Disconnection and reconnection; 6-channel ad analog acquisition; 4-way optocoupler input; 6-way relay control output; Save the power down state; 7-30v power supply, therefore, compared with the round robin mode, it greatly improves the work efficiency and reduces the cost of data flow.

Design

Since GPRS communication is a data packet communication network based on IP address, the monitoring center router and each end station are configured with fixed APN private network IP address, and the GPRS module of each end station communicates with the RTU of the center station.

1. Pipe network monitoring point

Pipe network monitoring points: each monitoring point collects data such as pressure, flow, liquid level and valve start state through the data acquisition module (RTU), and is connected with the GPRS data transmission terminal through the Ethernet interface. After the data is processed and the protocol is encapsulated through the built-in embedded processor in the GPRS data transmission terminal, it uses the unified SIM card of the mobile communication company for identity authentication and is connected with the GPRS network. Send to GPRS network.

2. Monitoring center

The router of the monitoring center applies to configure a fixed IP address and uses the APN special line provided by the local mobile communication company to connect with the GPRS network. The bandwidth of APN special line is 2m. When the number of pipe network monitoring points increases, the center can meet the demand without capacity expansion.

3. GPRS / GSM mobile data transmission network

The data collected by the on-site monitoring point is decoded and processed by the GSM network air interface function module at the same time, converted into the format of data transmission on the public network, transmitted through the GPRS wireless data network of China Mobile, and finally transmitted to the port address of the monitoring center through the APN private network.

4. Application system

After the data is transmitted to the data center, the monitoring system will display the data in real time on the one hand and store it in the database system regularly on the other hand. SCADA system management software can query real-time data and historical data, generate data statistical reports, generate data analysis curves and charts, etc. according to the actual needs of users. At the same time, SCADA system also carries out data interface with GIS system and OA system of dispatching center to provide timely and reliable basic data for GIS system.

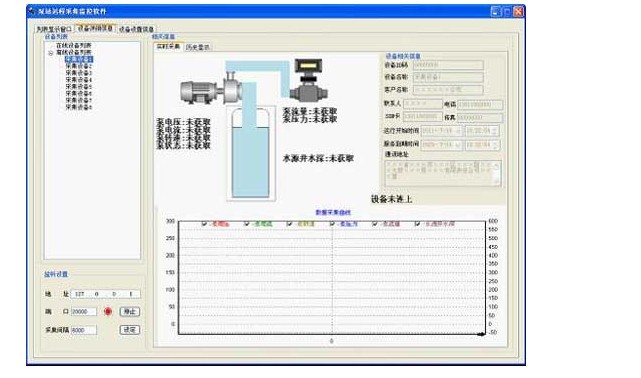

Monitoring software interface:

real-time display

1. The device list on the left shows the information of current online and offline devices. When the device is connected to the network, it will enter the "online device list" from the "offline device list". If the device is not online for a long time, it will enter the "offline device list" from the "online device list";

2. The upper right corner displays the equipment number, user name, contact person, telephone, fax, mobile phone, SIM card number, address and other information;

3. The upper left corner displays the pump speed, pump current, pool liquid level, flow, pressure and other information;

4. Real time display of water level, pump current, etc. under the window;

5. The middle text prompts the current equipment login time and the last time of collecting and returning data;

Real time interface of data acquisition and monitoring system

Historical records

1. Users can search history according to time period;

2. The history record will be drawn on the window in the form of curve, and the history record can be displayed under the window in the form of list. Through the history record, the equipment operation status and relevant trend can be viewed;

3. The history records queried at the same time can be exported to excel;

Data acquisition and monitoring system history

Effect drawing of configuration software

Users can customize the program through configuration software according to their needs, so that the interface expression form is more flexible;

conclusion

The SCADA system of water supply management constructed by GPRS network system has stable operation, accurate and timely data, and has gradually become an indispensable management tool and assistant for enterprise users. The original manual meter reading, manual input and analysis statistics are replaced by the system regularly and automatically generating daily data statistics reports, and the 24-hour manual duty is replaced by the automatic data monitoring system, which saves a lot of human resources and improves the work efficiency for the enterprise. The degree of automation of enterprises has been greatly improved. Moreover, in the near future, with the continuous development of enterprises and the increasing demand for the system, the monitoring scope of SCADA system will be further expanded, the function will be further improved, and it will play a greater role in the development of enterprises.

销售王经理

销售王经理

微信公众号

微信公众号