1、 Requirement description

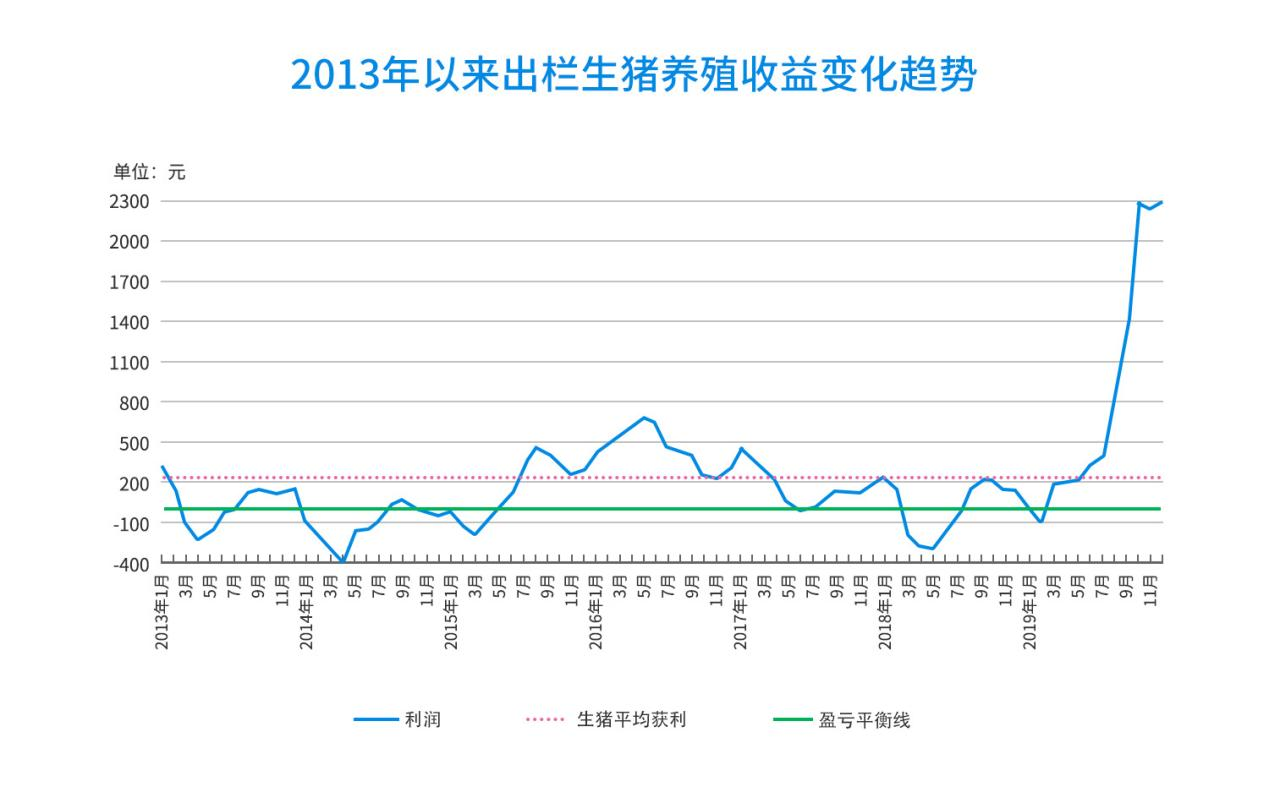

Animal husbandry is an important industry related to the national economy and the people's livelihood, and meat, egg and milk are important varieties of people's "vegetable basket". In recent years, the comprehensive production capacity of China's animal husbandry has been continuously enhanced, which has played an important role in ensuring national food security, prospering the rural economy and increasing the income of farmers and herdsmen. However, there are also prominent problems such as low quality and efficiency of industrial development, imperfect support and guarantee system and weak ability to resist various risks.

In 2020, the general office of the State Council issued the opinions on promoting the high-quality development of animal husbandry, requiring that the large-scale rate of livestock and poultry breeding and the comprehensive utilization rate of livestock and poultry manure and sewage reach more than 70% and 80% respectively by 2025 and more than 75% and 85% respectively by 2030. It proposed to speed up the construction of modern breeding system and strengthen the application of big data, artificial intelligence, cloud computing, Internet of things, mobile Internet and other technologies in animal husbandry, Improve the intelligent level of enclosure environmental regulation, precise feeding, animal disease monitoring and livestock and poultry product tracing, establish and improve the animal epidemic prevention system and improve the ability of animal epidemic prevention supervision and service.

2、 Communication architecture

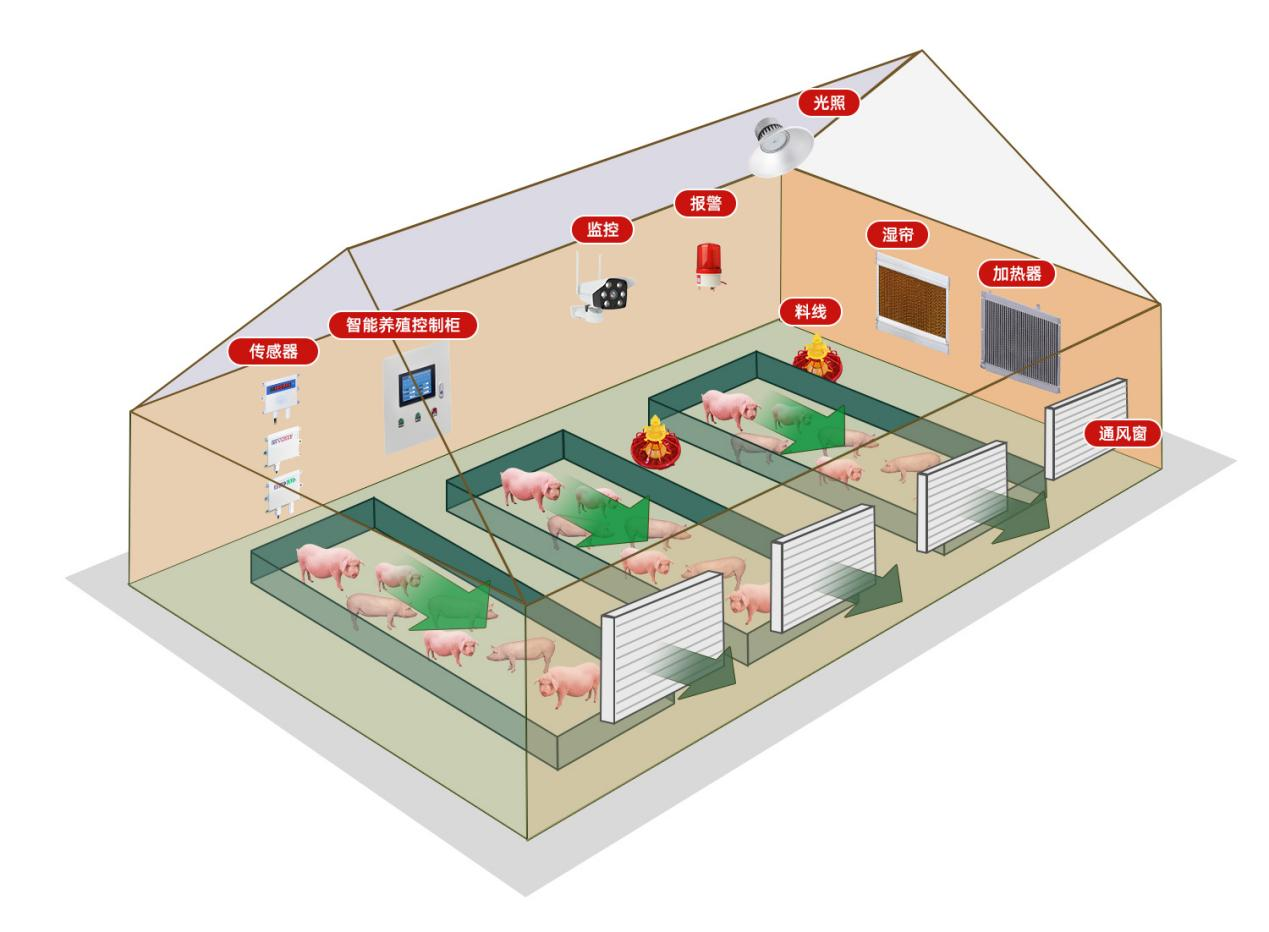

The intelligent livestock and poultry breeding monitoring system based on the Internet of things uses the Internet of things technology to collect the environmental information (carbon dioxide, ammonia, hydrogen sulfide, air temperature and humidity, etc.) of the livestock and poultry farm online through intelligent sensors around the production and management links of the facility livestock and poultry farm. At the same time, it integrates and transforms the existing environmental control equipment of the farm to realize the intelligent production and scientific management of livestock and poultry breeding. Farmers can grasp the environmental information of the breeding plant in real time, obtain abnormal alarm information in time, and remotely control the corresponding equipment according to the monitoring results, so as to ensure the healthy growth of livestock and poultry, improve the quality of livestock and poultry and reduce the occurrence of epidemic diseases.

3、 System composition and function

1. Intelligent environment monitoring

Online collection of environmental information (carbon dioxide, ammonia, hydrogen sulfide, air temperature and humidity, noise, dust, etc.) and growth behavior of livestock and poultry (eating, water diversion, excretion, etc.) through sensors, audio, video and remote transmission technology, real-time monitoring of breeding environmental information in the facility, timely early warning of abnormalities and reduction of losses.

Temperature and humidity

Compare indoor and outdoor air through indoor and outdoor temperature sensors. In hot summer, when the temperature in the house is higher than the external temperature, the fan can be started for air exchange to reduce the temperature in the house. Similarly, when the humidity in the house is high and the external humidity is high, it can also be ventilated and drained; In cold winter, especially in the north, it is necessary to carry out thermal insulation treatment for livestock and poultry breeding, and carry out heating (such as solar energy, electric stove, boiler heating) when appropriate.

Gas monitoring

The air in livestock farms contains ammonia, hydrogen sulfide and carbon dioxide. If these concentrations are too large and the time is long, the body will become worse and the resistance will be reduced. The incidence rate will be higher. Therefore, ventilation equipment, such as fans, should be installed to discharge dirty air in time and continuously enter fresh air. Deodorization equipment should be installed to blow feces and deodorize regularly. Through the ammonia, hydrogen sulfide, carbon dioxide and other gas sensors in livestock and poultry breeding, the concentration of relevant gases in the room is monitored in real time. When the concentration reaches a certain level, ventilation and deodorization shall be carried out to protect the air circulation and freshness in the house. The influence of ventilation on the temperature and humidity in the room should also be considered. Choose ventilation when the temperature is high in winter and cool night or morning in summer.

illumination

Sufficient illumination time is an important factor to ensure the healthy and rapid growth of cattle and efficient milk production. In case of dark light in livestock and poultry breeding on cloudy days or insufficient sunshine time in winter, auxiliary lighting shall be appropriately increased to make up for the lack of illumination due to weather and seasonal factors. Through the automatic adjustment function of illuminance in the automatic control system, the illuminance in livestock and poultry breeding can be adjusted freely.

pressure

Due to poor ventilation and other reasons in some times, there may be a difference between the pressure in livestock and poultry breeding and the outside world, which is not conducive to the circulation of internal and external gas, which is also a factor for the high concentration of harmful gas in the house. In case of internal and external pressure difference, relevant equipment shall be started for ventilation to ensure air circulation.

2. Intelligent water supply

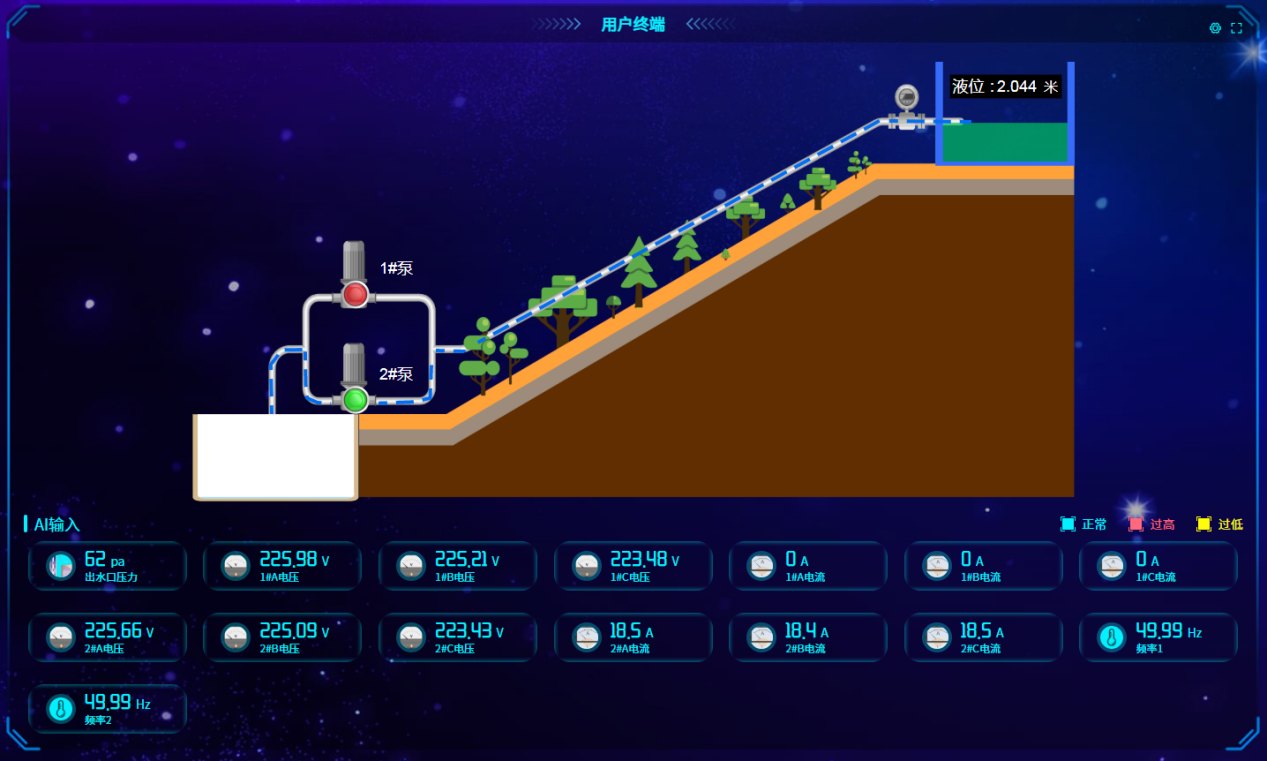

Site water pump monitoring

Through the monitoring platform, the staff can monitor the working state, working voltage and current data of the water pump in real time, and remotely and manually control the start and stop of the water pump;

Water supply of intelligent monitoring system for livestock breeding

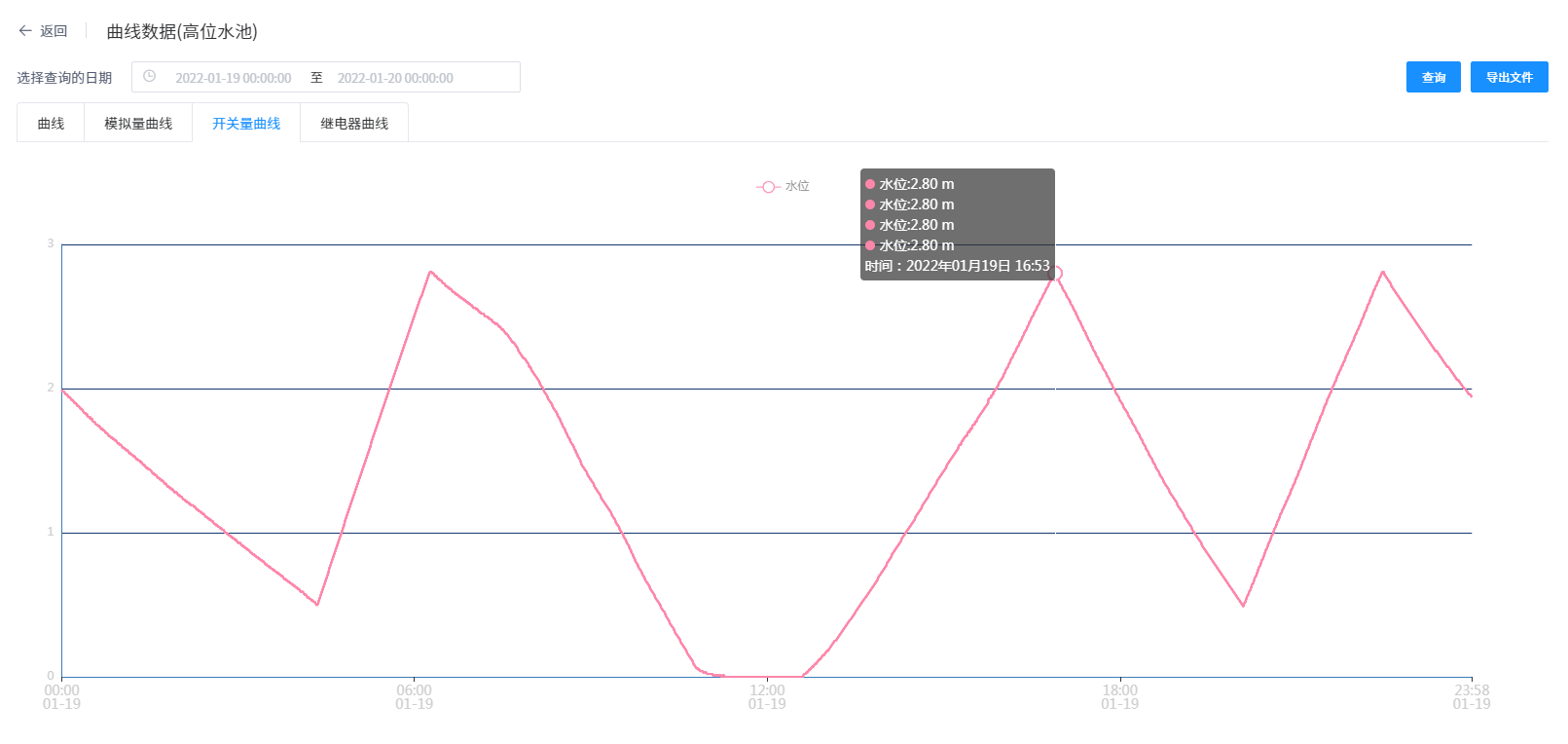

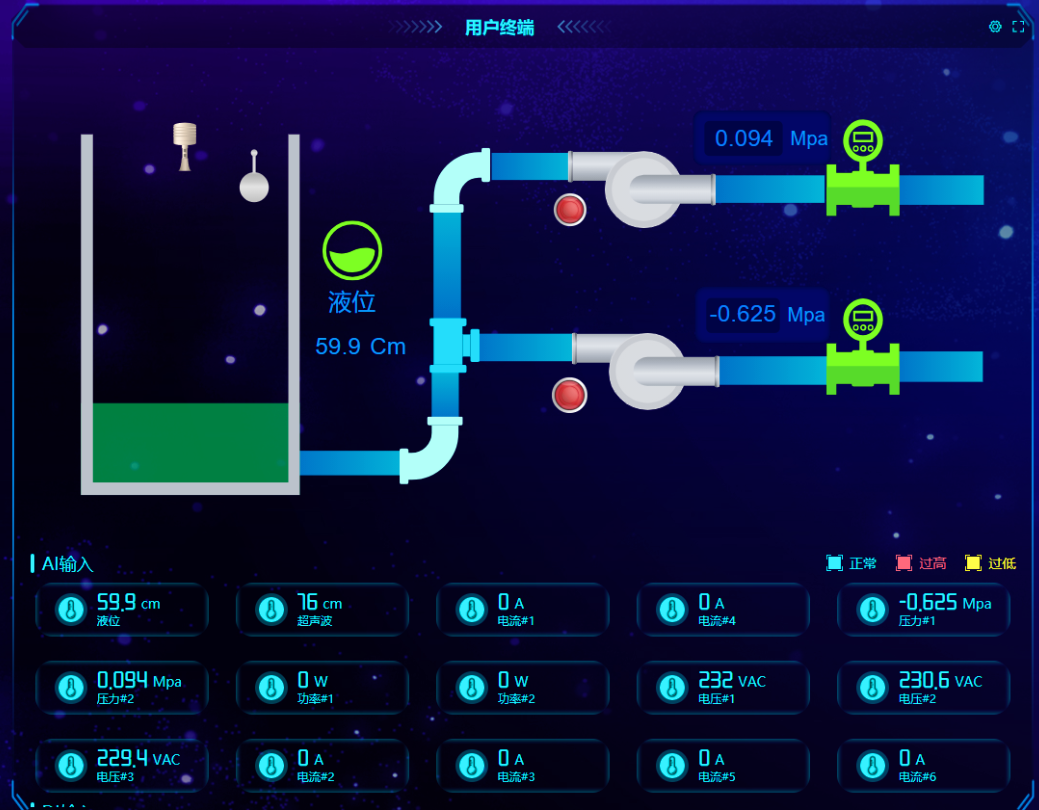

Liquid level remote monitoring

The monitoring platform displays the real-time data of the liquid level. When the liquid level is at the low water level, the pump will be automatically started to supply water, when it is at the high water level, the pump will be automatically stopped, and when the water level is ultra-low, the remote alarm will be sent to inform the staff;

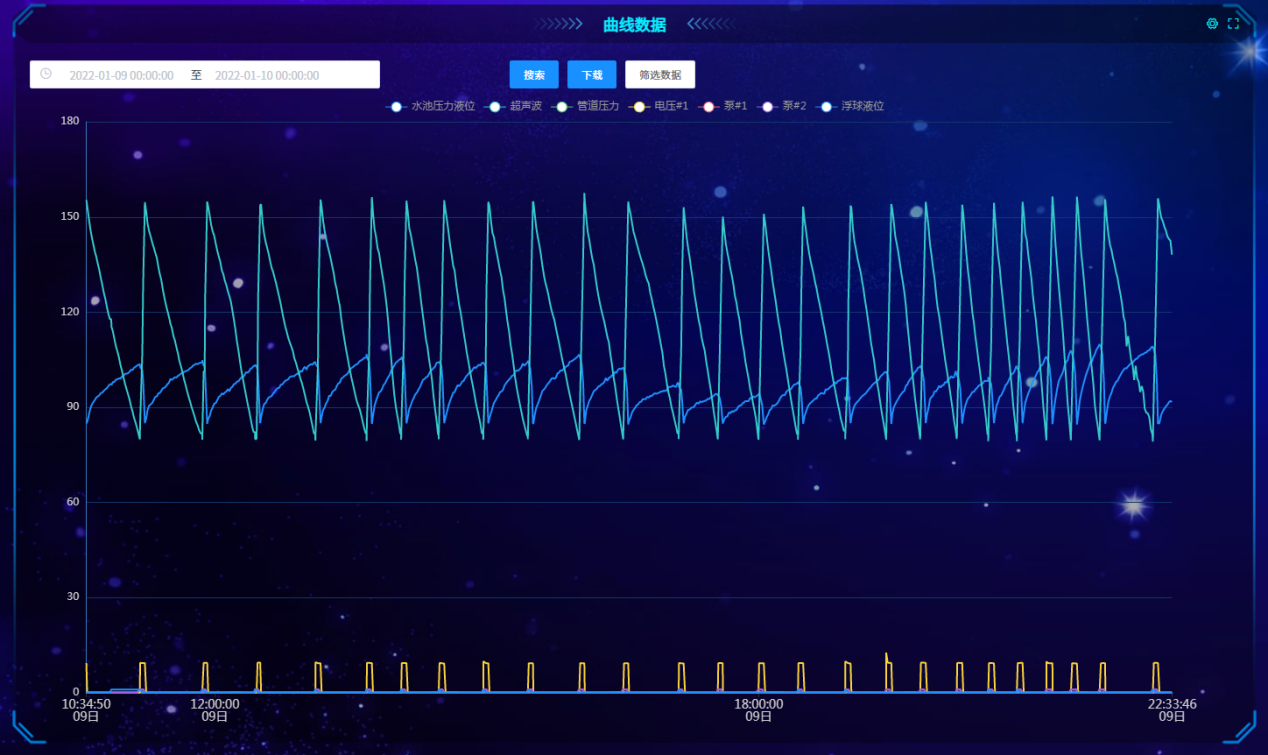

Data curve of intelligent monitoring system for livestock breeding

Intelligent monitoring system for livestock breeding

Water level data monitoring

Automatic start / stop of water pump

Two pumps work alternately

The water supply machine room is equipped with working pump and standby pump. When two or more pumps work, the water pump will be automatically switched regularly to protect the water pump unit and prolong the service life of the water pump;

Water pump switching of intelligent monitoring system for livestock breeding

Water monitoring

Remote real-time monitoring of the pressure and water consumption data of the water pipeline, automatic storage of the data, generation of curves and data reports for staff analysis.

Pump protection

By monitoring the start and stop state of the water pump and setting the protection of working voltage and current, when there are abnormal conditions such as phase loss, overpressure and overcurrent, the pump will be automatically stopped, and a remote alarm will be given to inform the staff to deal with it in time.

water quality monitoring

Industrial grade sensors such as water quality pH, residual chlorine and turbidity are used to detect the real-time data of the water quality of the water source. When the water quality parameters are abnormal, the disinfection equipment is automatically started for disinfection. The water quality data is automatically transmitted to the cloud for data recording once a minute, and the data is automatically sent to the staff mailbox for backup.

3. Energy consumption monitoring

Water consumption monitoring

Through the flowmeter, 4G / network and other remote transmission terminals, the water consumption of single pig house / cattle house / chicken house and the whole farm can be counted to form data curves and reports.

Power consumption monitoring

Through the intelligent power acquisition terminal / intelligent power meter and other equipment, realize the remote power acquisition of large power consuming equipment and power supply room, realize the data acquisition and monitoring of voltage, current, power factor and accumulated power, high and low temperature alarm and over-current and over-voltage alarm. The old meter does not have the function of communication remote transmission, so it needs to be changed and replaced with intelligent meter.

4. Unified regulation

Realize the centralized, remote and linkage control of the environment in the breeding house (including illumination, temperature, humidity, etc.). Feeding, humidity control, timing control, and light control.

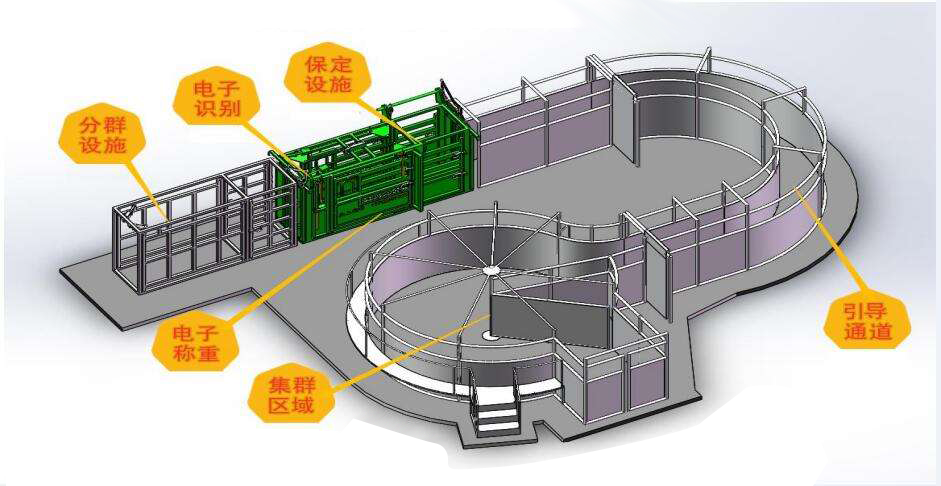

6. Monomer monitoring

The electronic temperature measurement ear mark, automatic weighing system, 4G / 5G / Lora and other wireless communication technologies are used to manage pigs and cattle, integrate the functions of temperature measurement, step measurement, positioning, weighing and grouping, accurately judge the health and weight status of livestock, achieve accurate disease early warning, and realize automatic and information management.

7. Video surveillance

Mobile monitoring equipment is set in the breeding area, which can realize real-time viewing of the on-site environment, remote real-time monitoring, review, transmission and storage of video information, timely find the problems encountered in the breeding process, find and analyze the causes, and ensure safe production.

4、 Related hardware equipment

Environmental monitoring cabinet

1.1 function description

Real time collection of ambient temperature and humidity data

Collect ammonia, hydrogen sulfide and air quality data in real time

Collect dust and noise data in real time

Support the control of local fan, roller shutter, excrement scraper, dust remover, feeder and heating system

Support the detection and feedback of working current of multi-channel control equipment

Support local sensor data display

Support local device working status display

Support local policy configuration

Support local parameter adjustment

Support remote control and telemetry

1.2 interface description

One way RS232

One way RS485

Ethernet, 2G or 4G all Netcom, WiFi interface

4-20mA acquisition of 4-16 channels

5-32 channel switching value signal acquisition

4-32 relay control outputs

Support 485 communication, sensor / instrument data access, etc.

Touch screen operation control

1.3 technical parameters

Power supply of control box: AC 220V

Main control power supply: dc12-24v

Main control power consumption: < 6W

Analog input: 4-20mA, 12bit accuracy

Switching value input: optocoupler isolation input

Switching value output: relay dry node output

Modbus RTU、Modbus TCP

Operating temperature: - 30 ~ 80 ℃

Humidity range: relative humidity 95% (no condensation)

1.4 main control selection

| 4 channels | Do control output | The maximum contact capacity of 4-way relay (dry contact) is 250VAC 10A / dc30v 10A |

| AI acquisition input | 5-way input, which can be connected to 5 sensors with 4-20mA or 0-10V output | |

| Di acquisition input | 5-way input, which can be connected to 5 dry contacts or NPN switching value | |

| 8 channels | Do control output | The maximum contact capacity of 8-way relay (dry contact) is 250VAC 10A / dc30v 10A |

| AI acquisition input | 8-way input, which can be connected to 8 sensors with 4-20mA or 0-10V output | |

| Di acquisition input | 8-way input, which can be connected to 8 dry contacts or NPN switching value | |

| 16 channels | Do control output | 16 way relay (dry contact) with maximum contact capacity of 250VAC 10A / dc30v 10A |

| AI acquisition input | 12 inputs, which can be connected to 12 sensors with 4-20mA or 0-10V output | |

| Di acquisition input | 12 inputs, which can be connected to 12 dry contacts or NPN SWITCHING values |

1.5 touch control

The control box integrates the touch screen integrated display control, which can display the actual sensor data on site, such as temperature and humidity, illumination, CO2, etc. It can also touch and control the actual output equipment on site, such as fan, roller shutter, manure scraper, etc.

1.6 sensor selection

| Sensor type | picture | parameter | explain |

| Air temperature and humidity |

| temperature range | -40-120℃ |

| Temperature accuracy | ±0.3℃ | ||

| Humidity range | 0-100% | ||

| Temperature accuracy | ±3.0% | ||

| ammonia |

| measuring range | 0-100ppm |

| measurement accuracy | ±1ppm | ||

| hydrogen sulfide |

| measuring range | 0-200ppm |

| measurement accuracy | ±1ppm | ||

| Noise |

| measuring range | 0-1000ppm |

| measurement accuracy | ±1ppm | ||

| 噪声 |

| measuring range | 30-130db |

| measurement accuracy | ±0.5db |

2. Water pump control cabinet

2.1 control cabinet

| Communication mode | 4G full Netcom / gateway / WiFi |

| Control output | Working pump |

| Standby pump | |

| Solenoid valve | |

| Work data collection | Water level of water tank |

| Water tank temperature | |

| Working voltage of water pump | |

| Working current of water pump | |

| Operating frequency of water pump | |

| Power consumption of water pump | |

| Pipeline pressure | |

| Pipeline instantaneous flow | |

| Cumulative flow of pipeline | |

| Water quality data collection | Water quality pH data |

| Water turbidity data | |

| Water quality residual chlorine data |

2.2 sensors

| Sensor type | purpose | parameter | explain |

| Liquid level sensor | Water level measurement of water storage tank | Temperature measurement range: | -50-150℃; |

| Output signal: | 4-20ma; | ||

| texture of material: | stainless steel | ||

| Electric quantity collection | Measure the voltage / current / power / electric quantity and other parameters of the water pump | Voltage range: | Ac0-500v (single phase / three phase) |

| Current range: | AC0-100A | ||

| RS485 interface; | |||

| Modbus Protocol | |||

| Pressure sensor | Measuring pipeline pressure | Measuring range: | 0-1Mpa; |

| 4-20mA output; | |||

| flow sensor | Measure the outlet flow | Measuring range: | 0-9999m ³/ H (pipe diameter to be confirmed); |

| RS485 interface; | |||

| Modbus Protocol | |||

| Water quality pH sensor | Measuring the pH value of water quality | Measuring range: | 0-14ph; |

| RS485 interface; | |||

| Modbus protocol. | |||

| Water quality residual chlorine sensor | Measurement of residual chlorine in water quality | Measuring range: | 0-20mg/L; |

| RS485 interface; | |||

| Modbus protocol. | |||

| Water turbidity sensor | Turbidity data for measuring water quality | Measuring range: | 0-4000NTU; |

| RS485 interface; | |||

| Modbus protocol. |

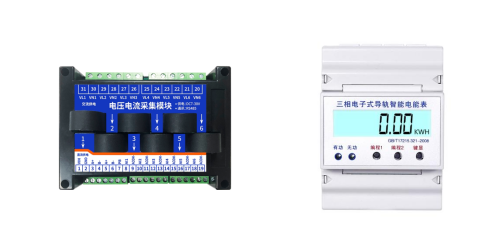

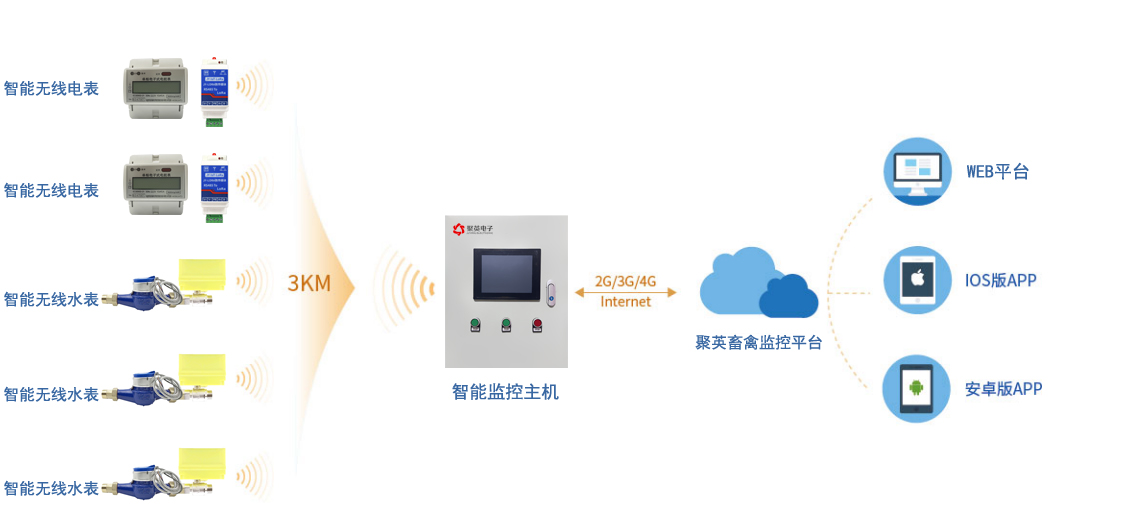

3. Energy consumption detection

Lora wireless mode is adopted to collect the data of water meter / electricity meter scattered in each room / dormitory area, and then transmit it to the intelligent monitoring host, which will upload it to the livestock and poultry monitoring platform through 2G / 3G / 4G or Ethernet WiFi for data monitoring and recording.

Lora transmission terminal adopts spread spectrum communication technology, multi-channel transmission, stable communication link, strong penetration, and the farthest communication distance can reach 3km.

3.1 monitoring cabinet

| category | Communication mode | Function description |

| Energy consumption monitoring host | Uplink: 4G / network port / WiFi; | As Lora acquisition host |

| Downlink: wireless Lora communication | Receive Lora intelligent water meter data; | |

| Receive Lora smart meter data; | ||

| Power supply 220VAC; | ||

| 470-510mhz band; | ||

| Up to 3km wireless transmission; |

3.2 wireless acquisition terminal

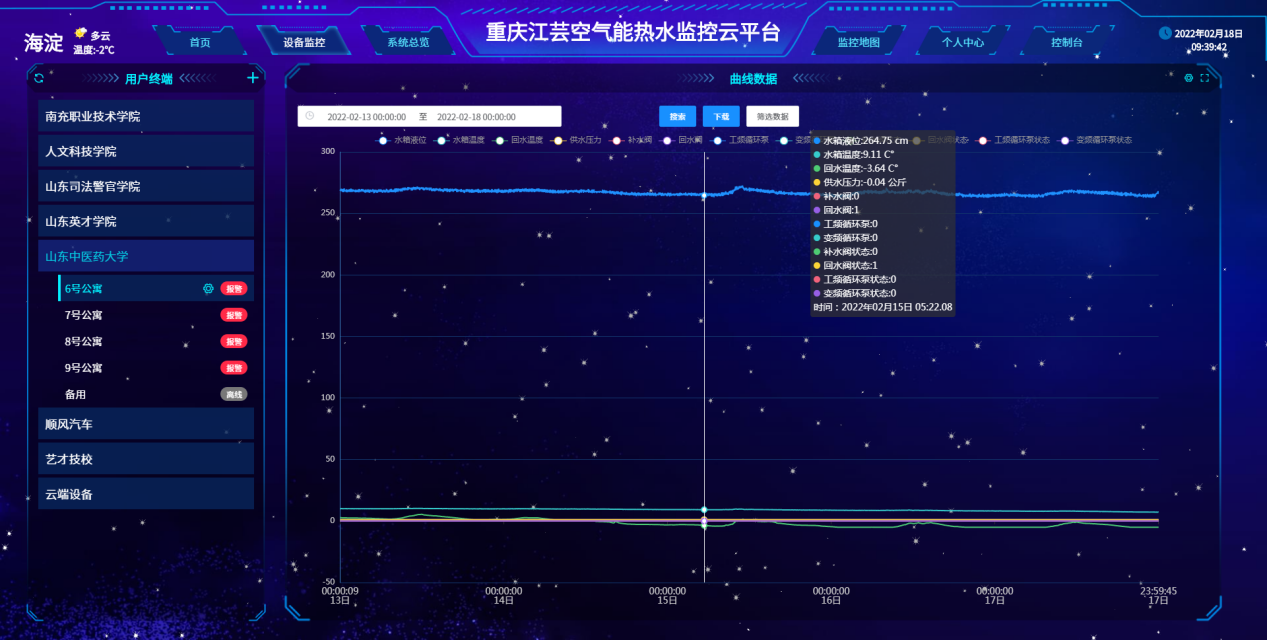

5、 Integrated intelligent breeding monitoring platform

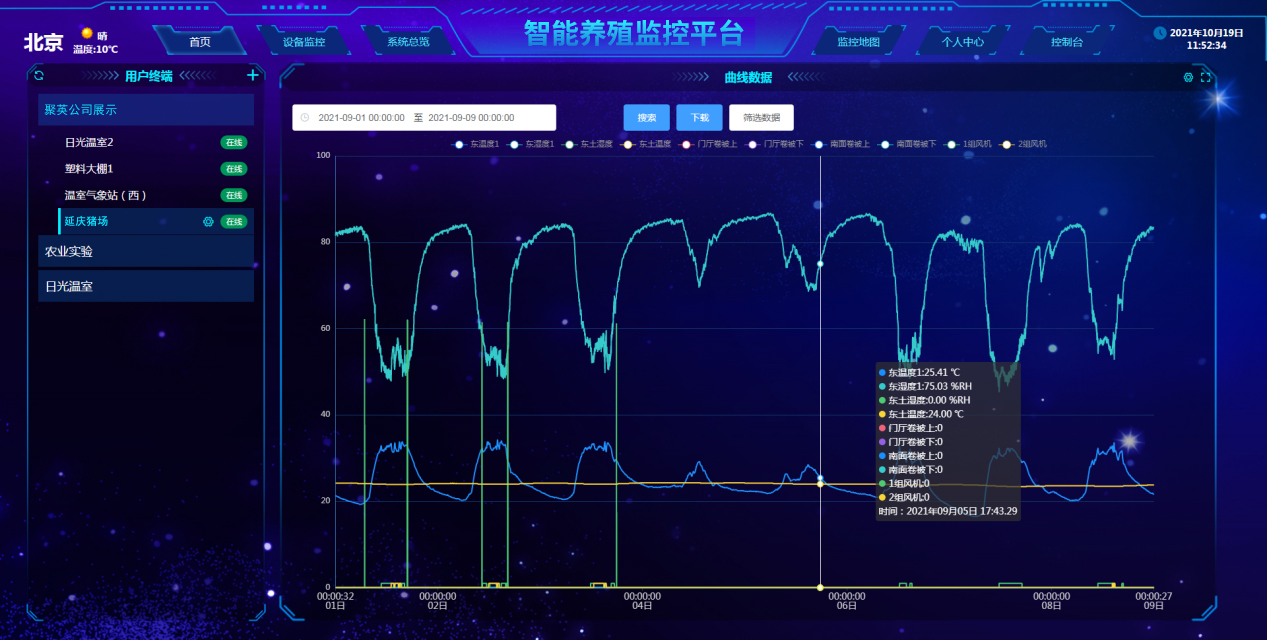

1. Configure scene monitoring

The livestock and poultry monitoring platform can provide a software interface according to the distribution of livestock and poultry breeding, distinguish the livestock and poultry breeding location, layout and location of each monitoring point on the interface, arrange according to the actual layout, realize the vivid image of the monitoring interface, and provide convenience for the actual monitoring.

(display of configuration monitoring platform)

2. Single house real-time monitoring

• 1. Provide real-time temperature and humidity, ammonia, carbon dioxide concentration, illumination and atmospheric pressure for each monitoring point;

2. Provide historical data query, support data query in any time period in the past, and provide data basis for some emergencies.

3. Provide historical music viewing. Through observing the change trend of a certain period in the past, we can summarize the corresponding change law, from which we can summarize some valuable experience.

• 4. Provide real-time alarm function. When any monitored parameter reaches the alarm condition, the monitoring software will provide sound and corresponding value flashing alarm to provide alarm prompt for relevant management personnel.

Single monitoring of intelligent monitoring system for livestock breeding

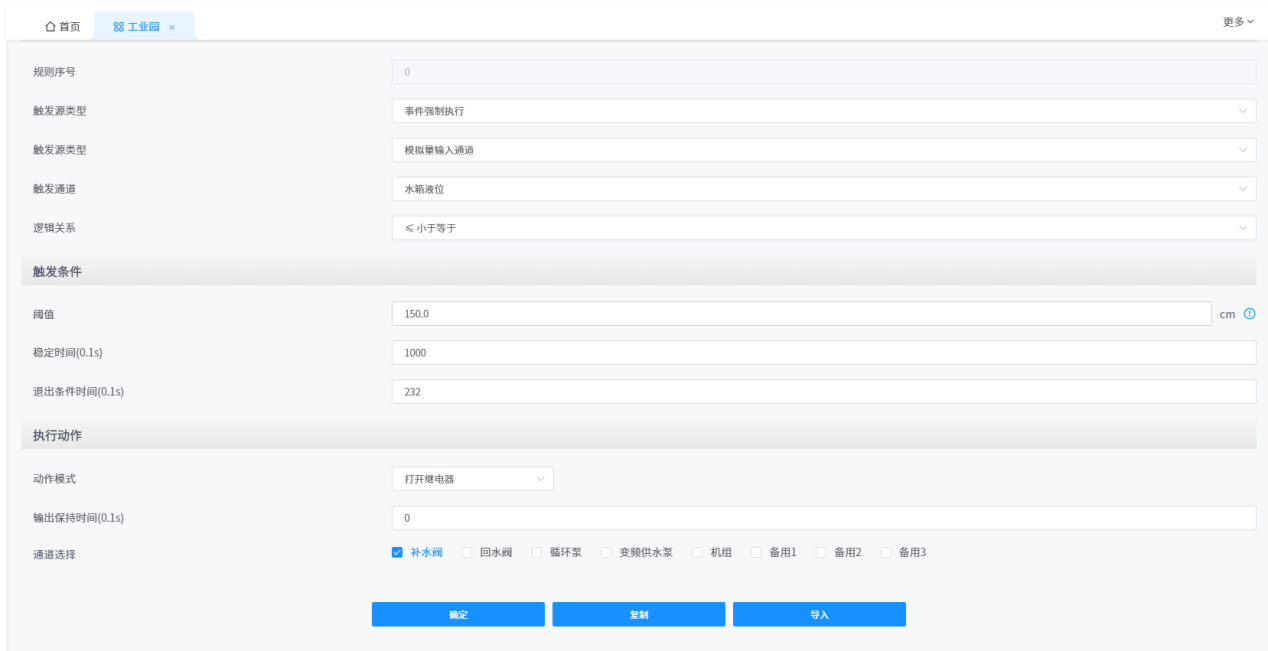

3. Intelligent logic control

Through the PLC intelligent automatic control function of the monitoring cabinet host, the intelligent and automatic regulation of the environmental regulation system, intelligent water supply system, energy saving and consumption reduction system and the unified regulation system of the whole farm can be realized. All regulation parameters can be remotely set and adjusted through the mobile app / computer monitoring platform, which takes effect in real time.

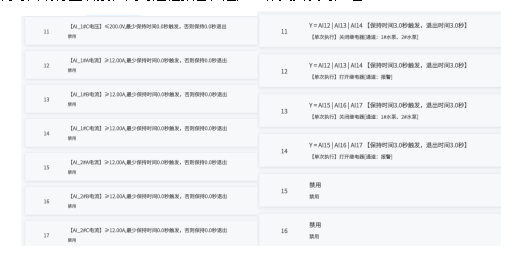

The following is part of the setting interface of water supply regulation parameters:

4. Centralized monitoring of equipment

Through the large screen monitoring platform in the management center, the staff can view the monitoring and operation data of all subsystem equipment in the farm at the same time for unified display.

5. Monitoring data alarm

When the environmental temperature and humidity, water level, voltage, current, electricity, water volume, livestock and poultry body temperature and other data of the environmental monitoring, water supply monitoring and energy consumption monitoring system are abnormal, multiple alarm notifications can be realized through the monitoring platform sound alarm prompt, mobile app message push, wechat message notification, staff mobile phone and SMS alarm, so as to facilitate the staff to deal with them in time and prevent potential accidents caused by missing reports.

The alarm includes four ways, such as APP message push, WeChat official account message notification, active call, SMS content alarm, etc., to ensure that users can notify users when they are abnormal.

6. User rights management

Different users have different permissions on the specified devices:

Management permission: device information management permission, delete device permission, control permission, sharing permission, device internal parameter configuration permission, cloud policy control configuration permission.

Edit permission: equipment information management permission.

Operation authority: the operation authority to remotely control the equipment.

Read only permission: view the real-time status of the device, view the historical data, curve and statistical report of the device.

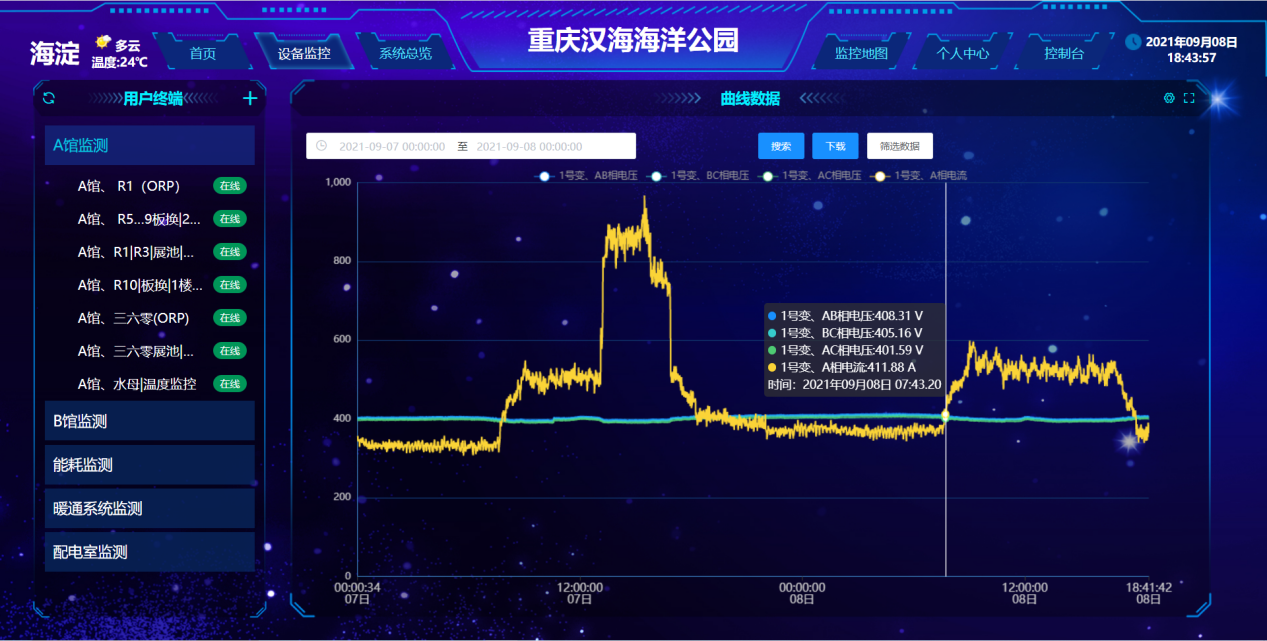

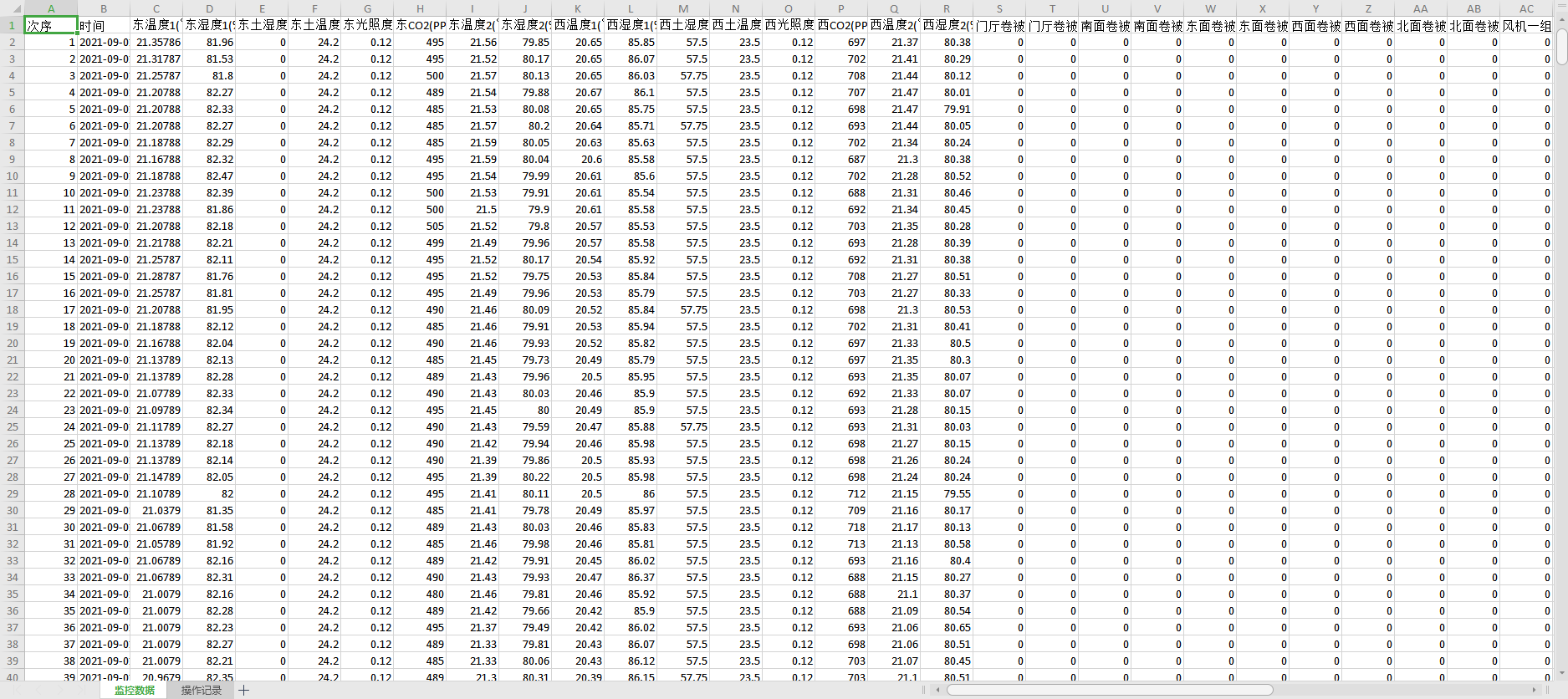

7. Data curve monitoring

The platform automatically records the sensor data and control data monitored by the equipment, once a minute, which can be displayed by curve query, or viewed by downloading and exporting excel table data. It also supports the automatic sending and receiving of backup data every day.

8. Video surveillance

The platform supports access to network cameras such as Hikvision / fluorite cloud, supports video monitoring and step-by-step display of data interface, and obtains real-time action feedback through video monitoring when feeding, fan and other equipment are remotely controlled.

6、 System application

Application scope of livestock and poultry intelligent breeding monitoring system:

Animal Husbandry Bureau, Animal Health Supervision Bureau, animal disease prevention and control center and other government regulatory departments;

Animal husbandry technology service (extension) center;

Large agricultural production and processing enterprises such as agricultural science and technology demonstration zones and farms.

The intelligent monitoring system for livestock and poultry breeding is applicable to cattle sheds, pig farms, duck houses, chicken houses, sheep farms and other places. It can realize the real-time wireless collection and monitoring of various environmental data, which is conducive to the scientific management of technicians.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts