The cold chain monitoring system is mainly used in the safety monitoring field of frozen and refrigerated products and strict detection of temperature requirements. It provides monitoring, early warning, analysis, data storage and other services for the temperature and humidity environment information of refrigerated products in production, transportation, distribution, storage and other links.

The cold chain monitoring system is based on wireless Internet of things technology to collect the temperature and humidity information of the environment in real time. It mainly adopts RTU terminal equipment and cold chain collector, and uploads it to the system monitoring platform through GPRS network or root. Through the real-time data changes on the system monitoring platform, managers can fully grasp the environmental information of refrigerated goods, which is convenient for decision-makers to make interpretation and decision-making.

System diagram:

System features:

1. Wireless networking

The acquisition node of the cold chain monitoring system uses wireless networking, and has mechanisms such as automatic frequency modulation, multipath routing, error correction coding, error retransmission and adaptive rate, which can ensure the reliability and stability of data transmission to the greatest extent.

Compared with wired networking, wireless networking has great advantages not only in the installation difficulty and cost of the new system, but also in the upgrading of the old system.

2. Ultra low power consumption

The acquisition node of the monitoring system can be powered by battery. The working current of the equipment mainly includes control chip and RF transmission.

Working current of chip: 3mA

RF transmission working current: 25mA sleep current: 0.5ua

According to the calculation that the equipment works once every 5 minutes and works for 1s each time, the power consumption per hour is 0.09ma/h, and the power consumption per year is about 790ma / h, that is to say, as long as a 1600ma / h battery can make the equipment work for 2 years.

Main equipment of the system

1. Concentrator:

The concentrator used in the system is RTU terminal, which is equivalent to the equipment "black box". It is responsible for on-site data acquisition, storage, transmission and control. It is the hardware basis for the on-site implementation of the whole system. There are two communication interfaces between rtu6640 and upper computer: GPRS and rs482:

GPRS is suitable for remote environmental monitoring, such as the logistics link of the cold chain.

RS485 is applicable to local environmental monitoring, such as production and storage of cold chain.

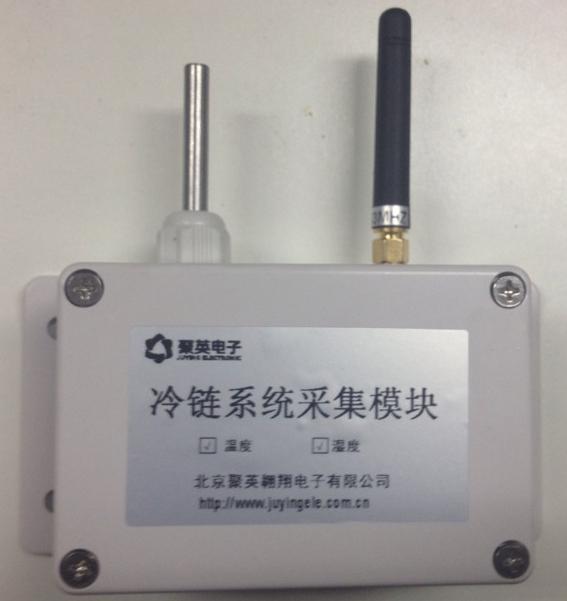

2. Cold chain collector:

The collector is responsible for collecting and uploading field data. It has two working modes.

Timed wake-up

In this mode, the device wakes up once every interval (e.g. 5 minutes). After completing the task of collecting and uploading environmental information, it enters the low-power mode until it wakes up next time.

Fixed point wake-up

In this mode, the equipment is awakened by the concentrator on site. The concentrator can wake up the whole network or the specified equipment. After completing the task of collecting and uploading environmental information, the device also enters the low-power mode again.

销售王经理

销售王经理

微信公众号

微信公众号