At present, there are more than 450000 sets of pumping units in China, but more than 90% of the pumping unit working condition measurement system with power diagram as the core (including liquid level, pressure, temperature and current) is in manual inspection mode. There are some problems in parameter acquisition, such as large lag, low precision, high cost and serious pollution. A traditional oil production plant with an annual output of 2 million tons of oil will cause direct and indirect economic losses of 93 million yuan every year. However, a micro enterprise - remote measurement and control technology (jy-rtu6640) makes the above problems perplexing China's oil production history, and will provide a powerful bottom core high-level measurement and control system for the digitization, informatization and networking of China's oil fields.

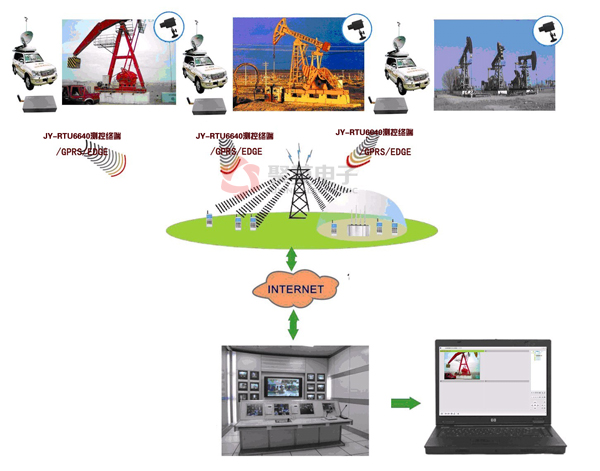

Oil well remote measurement and control system, including power diagram remote measuring instrument, dynamic liquid level remote measuring instrument, wireless pressure measuring instrument, stroke current wireless measuring instrument and related system software, is the most comprehensive and perfect measurement system for pumping units. The system is an Internet of things system composed of a variety of intelligent sensors for oil well production measurement and control. After the system is installed, the oil field management personnel can grasp the working condition of the pumping unit in the whole Tibetan area in real time in the machine room of the central station, collect all-weather data, find production abnormalities and give an alarm in time, so as to avoid ineffective oil well production. Among them, rtu6640 series oil well dynamic liquid level remote measuring instrument has a measuring range of more than 3000 meters with unique ultra-high-precision echo location technology. It is the only product in China that can realize long-term unattended remote measurement of well depth. The enterprise was supported by the national technology innovation fund for small and medium-sized scientific and technological enterprises.

In the past two years, the product has been tried in many oilfields. Compared with similar products, the product is convenient, low consumption and efficient. It is an efficient means to improve the level of oilfield production management, an effective way to achieve oilfield production safety and environmental protection, and an effective way to reduce costs and increase efficiency of oilfield enterprises.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts