1、 Overview

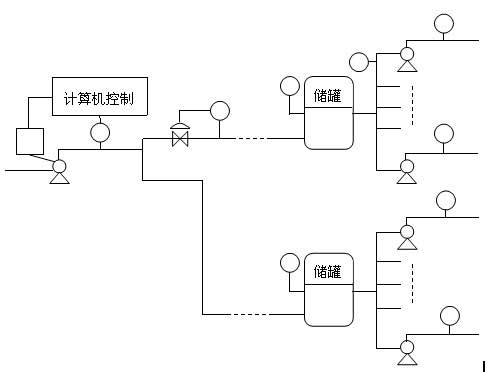

An important means for the oilfield to realize the third oil recovery is the oil recovery method of polymer injection. The oilfield is remotely monitored and controlled. The process of remote measurement and control is to mix the polymer and water in a certain proportion in the configuration station, and after a certain period of maturation, it is transported to each injection station through the export pump, diluted with clean water in the injection station, and then injected into the well. At present, the "centralized configuration and decentralized injection" polymer configuration system is popularized, that is, one polymer configuration station corresponds to multiple injection stations.

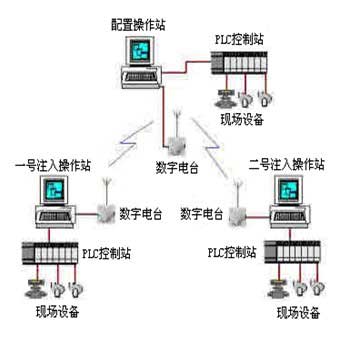

At present, the control of configuration and injection is relatively independent, and there is no control system connecting configuration and injection. Due to the vast area of the oilfield, it is very difficult to realize stable and effective centralized control. Moreover, the distance between stations is far, and it is impossible to use conventional control. By using the built-in control algorithm of force control software and using radio remote communication components, a coordinated and unified control system between configuration station and injection station is established.

An oil field is now in the stage of tertiary oil recovery. Polymer mother liquor is the main injection wellhead component of tertiary oil recovery, so the large-scale preparation of mother liquor is essential, so it is necessary to build an automatic and large-scale polymer preparation station.

From the actual situation on site, there is a common problem in the control system of most "injection distribution stations": the lack of a set of practical and feasible comprehensive control system. On the one hand, although the automatic monitoring system has been realized in the configuration station, it is still manually controlled in the injection station. The workers in the injection station should always monitor the changes of liquid level, pressure and flow in the liquid storage tank and make manual adjustment. They should also contact the configuration station by telephone to inform the configuration station to adjust the frequency of frequency converter of export pump and the opening of regulating valve, The specific adjustment amount needs to be contacted by both parties for many times and adjusted continuously, so as to gradually approach the required goal. It is not only labor-intensive, but also inefficient. On the other hand, due to the long distance between the configuration station and the injection station, the straight-line distance is generally more than 1.5km, and there are swamps in the middle interval, which is not only difficult to erect the line, but also inconvenient for maintenance.

This project upgrades and replaces the monitoring system composed of advanced PLC and upper unit software for the devices dominated by manual measurement and control in the past experimental stage, and achieves satisfactory results in actual production.

2、 Design scheme and polymer configuration

2.1 scheme design

The system takes PLC as the main control body and configures configuration software as the monitoring system to realize the data monitoring and process control of the system. The system network structure is simple. PLC collects data from various equipment sensors and pressure instruments in the form of industrial bus, monitors and processes field switches and valves through software design control program, and can operate in a variety of working modes, such as local operation mode, remote operation mode, automatic process control, etc., so as to centrally control and manage the equipment, And monitor its operation status to facilitate fault handling. The data communication between the PLC control station and the monitoring computer is carried out through Ethernet. The control terminals are set in the monitoring center and monitored by the staff.

The upper computer designs the monitoring screen according to the process flow, which has the functions of data acquisition and display, data storage and management, alarm output, historical data storage and report generation, and is connected to the network printer to facilitate the generation of various report files in the production process. The system designs a redundant configuration mode. The two upper computers are connected through Ethernet. The host communicates with the PLC in normal conditions, while the slave communicates with the lower control system in case of abnormality of the host, and the data is backed up synchronously, so as to ensure the consistency and integrity of the data and ensure the safe and stable operation of the production.

Polymer configuration

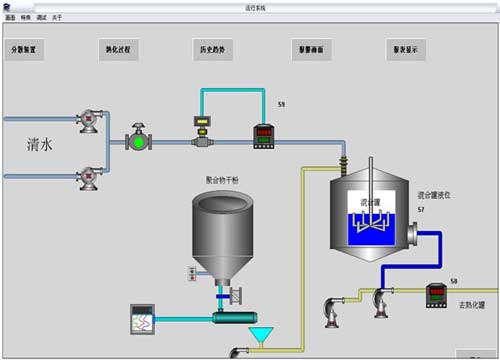

Figure 2-1 polymer configuration

According to the needs of tertiary oil recovery, the gelled polymer configuration system is widely used in various oil production operation areas. The system can be divided into two parts: polymer dispersion and polymer solution maturation. The dispersing device plays an important role in the whole system. Its function is to mix the dry powdered polymer and water into a uniform solution that meets the concentration requirements. Because the configuration concentration accuracy of polymer solution requires high, and the polymer is easy to produce "fish beads" and "Stickiness" when encountering water, this part should be fully automatically controlled by computer. In addition, the device can also be made into a movable vehicle mounted form. The curing system is mainly completed in the field curing tank, and the control form of this part can be manual or computer.

The control scheme of the computer monitoring system is to use the automatic control system composed of industrial control computer and programmable controller to replace the original manual control system. The configuration station and injection station fully realize automatic control, and carry out data communication through digital radio to achieve the linkage control between the configuration station and the two injection stations. The control system of each station forms an organic whole system, We should change the situation of self-contained division in the past. This can not only reduce the labor intensity of workers and improve work efficiency, but also well coordinate the relationship between polymer configuration and injection volume, effectively reduce the cost and achieve the best configuration effect.

When the liquid level of the liquid storage tank changes, it is necessary to adjust the output frequency of the frequency converter of the export pump of the configuration station to adjust the speed of the export pump, and adjust the opening of the outlet valve of the export pump. When the opening of the valve cannot make the flow meet the requirements, fine tune the frequency converter, so as to control the polymer flow output from the configuration station to the injection station to adjust the liquid level of the liquid storage tank of the injection station. The polymer configuration is shown in Figure 2-1.

The oil field polymer configuration control system includes dispersion part and ripening part.

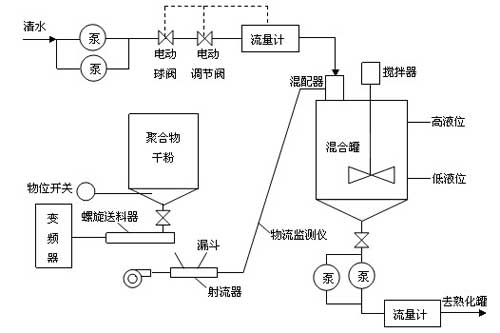

(1) The process flow chart of dispersion part is shown in Figure 2-2.

Figure 2-2 flow chart of decentralized control

The control process is as follows: after supplying 0.4-0.5mpa pressure water, dry powder and power (220V, 380V). This part can carry out automatic production and liquid preparation according to the required liquid preparation concentration (the concentration can be adjusted), and the error is less than ± 5%. The clean water is pumped by the clean water pump, and the polymer is sent by the polymer tank through the blower jet. The clean water and polymer are mixed in the mixer and enter the mixing tank, which is stirred to produce the required solution, and then pumped to the local curing tank by the liquid transfer pump. So far, the decentralization process of the whole configuration has been completed.

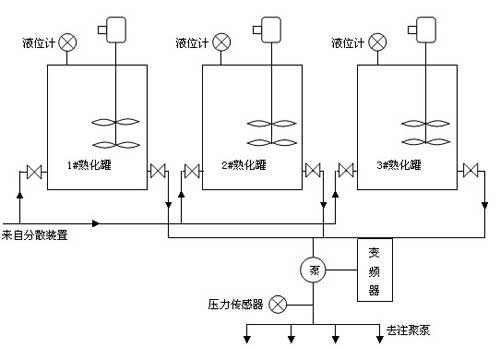

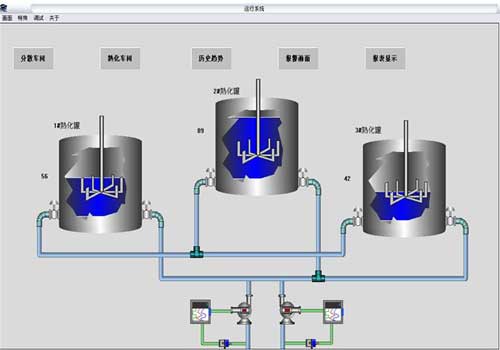

(2) The flow chart of ripening part is shown in Figure 2-3.

Figure 2-3 ripening control flow chart

As shown in Figure 2-3, the polymer solution configured by the dispersion device is pumped into three curing tanks through the transfer pump. In the curing tank, the solution formed by stirring for more than 120min can meet the service standard. It is pumped out through the export pump and sent to each injection station.

3、 System configuration and function realization

3.1 system configuration

Hardware: the monitoring center is equipped with 2 industrial computers, installed with Kingview software and equipped with ash removal monitoring system for staff monitoring operation, and equipped with dual computer hot standby mode; At the same time, Omron PLC is installed to collect and monitor the field equipment, and connected to two upper computers through Ethernet switch for data communication.

Software: the monitoring software of ash removal system designed by Kingview manages and controls the collected data and process flow; The PLC programming software will download the control program to the PLC and configure the PLC network. The hardware configuration has expansibility, which is used to add equipment or communicate with other systems.

The logic and sequence control part of this scheme is completed by PLC, and the picture monitoring of the whole control process is completed by the force control monitoring software. The whole control system is divided into two parts, decentralized and mature. Two subroutines can be formed in PLC and called on demand. The screen monitoring can also be divided into two parts and displayed separately. The structure of the automatic monitoring system is shown in Figure 3-1.

Figure 3-1 structure diagram of automatic monitoring system

3.2 function realization

When establishing dynamic variables such as liquid level of mixing tank and ripening tank, flowmeter reading, dynamic liquid level display in tank, curve and alarm in the system, it is necessary to first establish simulation PLC in "equipment", establish required dynamic variables in "data dictionary", and set connection equipment, register type, data type and other information. The display of variable numbers shall be set to "##. ##. ##" in the monitoring screen; The dynamic liquid level in the pipe is displayed by setting the background color and filling color. After setting, it is connected with the corresponding dynamic variables. The realization of the button function requires the input of appropriate commands:

Exit: exit (0);

Switching screen: showpicture ('* * * *'); ("* * * *" indicates the switched screen)

Input prompt: it supports the working mode of touch screen, and a soft keyboard appears wherever there is input. Formula management can be carried out, and the operator can adjust the proportion of solution according to needs.

According to the process requirements of the system, the system designs a rich picture display, vividly and dynamically display the layout of decentralized system and ripening system, and uses different colors to reflect the operation status of each equipment. The system has perfect alarm processing. When the system gives an alarm, it can display the alarm screen, display the alarm content, and record the alarm for query and printing.

Screen monitoring: including process monitoring screen, process parameter display, alarm screen, trend screen and report screen. The process monitoring screen is shown in Figure 3-3.

Figure 3-3 process monitoring screen

Figure 3-3 is mainly the flow chart of the dispersion device. The clean water flows to the mixing tank through the water pump, electric ball valve and electric regulating valve; At the same time, the polymer dry powder flows into the mixing tank through the screw feeder, funnel, jet and mixer. After mixing the two raw materials in the mixing tank, they flow to the curing tank.

The curing process is shown in Figure 3-4. The mixture from the dispersion unit flows to the polymer injection pump after passing through No. 1, No. 2 and No. 3 curing tanks respectively. The system has perfect alarm processing. When the system gives an alarm, it can display the alarm screen, display the alarm content, and record the alarm.

The process flow is truly reflected on the process picture, which has real-time, three-dimensional and dynamic effects. The screen not only has the function of directly displaying the liquid level, volume and weight of each tank farm, but also has the function of dynamic medium flow direction and various alarm functions. The alarm system is shown in the figure

Figure 3-4 curing process screen

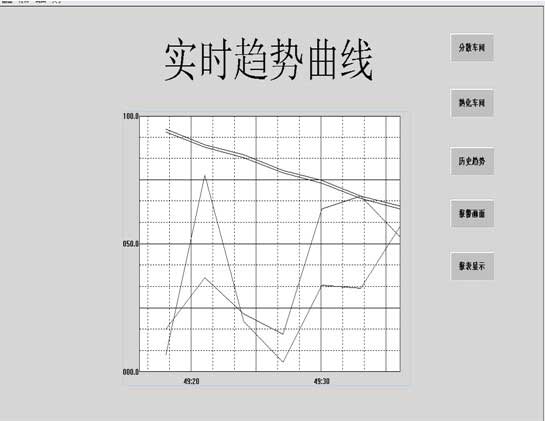

Each liquid level has the function of historical trend and real-time trend.

The maximum historical trend can reach 350 hours. The operator can find it at

any time according to requirements.

It has voice alarm function for important production data. When the parameter reaches the high limit alarm or low limit alarm, it will be directly output by voice to remind the operator to pay attention.

The alarm screen includes an alarm for the abnormal conditions of the decentralized workshop and the ripening workshop. When the liquid level in the mixing tank in the dispersion workshop is abnormal, the alarm window will truthfully feed back the event date, event time, alarm date, alarm time, variable name, alarm type, limit value, priority, operator and other information. When the liquid level of any of the three curing tanks in the curing workshop is too high or too low, the system will also send an alarm. The alarms between the tanks do not conflict, and multiple alarm messages can be displayed at the same time.

Figure 3-6 shows the liquid level curve of mixing tank and No. 1, 2 and 3 curing tank.

Figure 3-5 alarm screen

Figure 3-6 real time trend curve screen

Polymer flooding technology can be divided into polymer flooding, alkali polymer flooding, surfactant polymer miscible flooding and alkali surfactant polymer miscible flooding. In practical application, acrylamide polymers with different molecular weight are often used according to different reservoir physical properties (low permeability, medium permeability and high permeability reservoirs). For example, the molecular weight of HPAM used for oil displacement in Daqing Oilfield in China should not be less than 10 million because of its high permeability. However, at present, the production of automobile industry is difficult, and most of them are introduced from Britain, Japan and other countries. The products have emulsion products, water-soluble gel products and powdery products. Because of its large dosage and stable market, it is necessary to develop and study the industrial synthesis technology of high molecular weight acrylamide polymers in China.

4、 Conclusion and experience

This case has a preliminary understanding of Kingview, and has greatly improved its application and software simulation. The Oilfield Polymer control system has a reliable PLC to centrally control the equipment, and is configured with configuration software as the monitoring system to realize the data monitoring and process control of the system. The system network structure is simple. PLC collects data from various equipment sensors and pressure instruments in the form of industrial bus, monitors and processes field switches and valves through software design control program, and can operate in a variety of working modes, such as local operation mode, remote operation mode, automatic process control, etc., so as to centrally control and manage the equipment, And monitor its operation status to facilitate fault handling.

reference

[1] Tong Qiming Application of control system digital simulation and monitoring configuration software [M] Beijing: Science Press, 2006

[2] Wang Yamin Design and development of configuration software [M] Shaanxi: Xi'an University of Electronic Science and Technology Press, 2003

[3] Yuan Xiuying Configuration control technology [M] Beijing: Electronic Industry Press, 2003

[4] Qin Guili, Wu Shangqing Configuration software control technology [M] Beijing: Beijing University of Technology Press, 2007

[5] Yan Yingfu Introduction to monitoring configuration software and PLC [M] Beijing: People's Posts and Telecommunications Press, 2006

[6] Ma Yuchun Computer monitoring technology and system development [M] Beijing: Tsinghua University Press, 2007

[7] Cai Yanjie Polymer flooding injection production adjustment technology [M] China Petrochemical Press, 2002

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts