The pressure, flow and flow direction of the pipe network are important monitoring contents in the water supply dispatching system. The measurement and control terminal is installed on the monitoring site to collect the pressure, flow and flow direction of the pipe network and transmit the information to the dispatching center.

At present, the measurement and control terminals selected by domestic water companies are different. Some choose data acquisition module plus radio, some choose data acquisition module plus wired modem, and some choose PLC plus GPRS. Although these devices can meet the needs of the site, they also have some shortcomings, such as large amount of radio maintenance, high cost of wired modem, high power consumption of ordinary GPRS, etc.

According to the general requirements of the water department and the characteristics of the water department's pipe network monitoring, a low-power battery powered RTU measurement and control terminal is designed. The terminal scientifically integrates the micro power measurement and control technology and GPRS communication technology, which can meet the requirements of different use environments of water supply pipe network monitoring. Now the design features and application features of the equipment are introduced as follows:

1、 Design features

1. Modular structure design

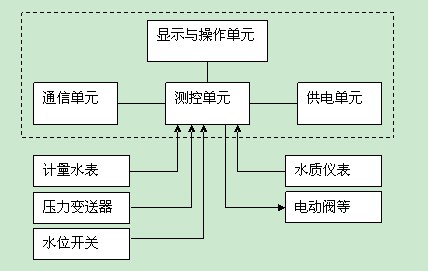

The low-power battery powered RTU measurement and control terminal is mainly composed of four parts: Measurement and control unit, communication unit, display and operation unit and power supply unit.

The measurement and control unit is the core of the terminal equipment. It is responsible for collecting the current or voltage signal of the field pressure transmitter, the pulse signal or digital signal of the flow instrument, the analog signal or digital signal of the water quality monitoring equipment, providing relay signal output, providing 5V / 12V / 24V DC power supply for the field transmitter and other equipment, and controlling the communication unit and power supply unit.

The communication unit is mainly responsible for the communication between the site and the dispatching center. GPRS wireless communication mode is adopted and compatible with GSM short message communication mode. There are three working modes: normal mode, standby mode and sleep mode. Different working modes are selected for different power supply modes.

The display and operation unit is mainly responsible for the display of on-site monitoring data and on-site parameters. The key operation can query the monitoring data and set parameters. The Chinese LCD display and waterproof magnetic induction key are adopted. The power supply unit mainly provides working power for terminal equipment and supports three power supply modes: municipal power supply, solar power supply and battery pack power supply. Different power supply modes are selected for different site environments.

2. Waterproof design

Urban pressure monitoring points are distributed along the pipe network, and most of the monitoring terminal equipment are installed in the observation well, which requires the equipment to be waterproof and moisture-proof. The low-power battery powered RTU measurement and control terminal adopts the following waterproof design to ensure the waterproof effect.

Shell waterproof design:

The material is reinforced nylon. Its waterproof, moisture-proof, anti-corrosion, frost resistance, heat resistance, strength, toughness and other indicators meet the observation of underground use environment, and its weight is light.

Between the upper and lower covers of the terminal and the inlet and outlet are places where water and moisture can easily enter. The upper and lower covers of the terminal are sealed with H-shaped sealing strips, which surround the contact wall between the upper and lower covers from three directions. The upper and lower covers are fastened with 14 stainless steel bolts, and the distance between two adjacent bolts is 5cm, ensuring the fastening strength; Waterproof joints shall be used at the inlet and outlet of the line. The waterproof joint and the shell shall be sealed with O-ring and waterproof glue, and the inlet and outlet line and waterproof joint shall be sealed with sealant sleeve and sealant. The protection grade of the terminal can reach IP68.

Secondary waterproof design

In the process of field installation and maintenance of low-power battery powered RTU measurement and control terminal, sometimes the waterproof performance of the terminal may be reduced due to the non-standard operation of installers, such as insufficient fastening strength of screws. In order to ensure that the terminal equipment will not be soaked by the accumulated water in the well, we have specially designed a waterproof cover for its use environment. The terminal equipment is installed in the waterproof cover, and the opening of the waterproof cover is fixed on the well wall downward. When the accumulated water is higher than the waterproof cover, the accumulated water can be prevented from contacting the terminal equipment due to the air pressure in the cover.

Wiring waterproof design:

When the low-power battery powered RTU measurement and control terminal is installed underground, it shall be equipped with waterproof cable and waterproof junction box. Waterproof shall be done between the terminal and waterproof cable according to the above requirements. The cable provided by pressure transmitter or other instruments and the cable of the terminal shall be connected on the terminal in the waterproof box. After connection, waterproof glue shall be injected into the waterproof box.

Use characteristics

1. Power supply and working mode

The dispatching center has high requirements for the real-time monitoring of pipe network pressure, but many pressure measuring points often do not have power supply conditions. Due to the limitations of power consumption and working mode, it is difficult for general monitoring equipment to meet the needs of customers. According to the characteristics of low-power battery powered RTU measurement and control terminal, we plan and design three working modes:

Normal mode

The measuring point is equipped with 220V mains power or solar power supply conditions. The terminal equipment can meet the requirements of frequent data acquisition and transmission, and support real-time data reporting and active inquiry of the dispatching center.

standby mode

There is no power supply condition for the measuring point, and the rechargeable high-capacity battery is selected for power supply. Due to the limitation of battery power, it is necessary to reasonably set the data acquisition interval and data transmission interval of the terminal equipment. When sending data wirelessly, the power consumption of the device is large, and the power consumption during acquisition can be ignored. The terminal equipment supports data regular reporting, data overrun reporting and active inquiry of the dispatching center.

The battery is fixed on the bracket and equipped with a waterproof shell. The low-power battery powered RTU measurement and control terminal can detect the voltage of the battery. When the voltage exceeds the lower limit, the battery needs to be charged. The charging cycle is related to the transmission frequency and the capacity of the optional battery. A 100Ah battery can generally support the normal operation of terminal equipment for 3-4 months.

sleep mode

There is no power supply condition for the measuring point, and the disposable lithium battery pack is selected for power supply. The battery pack is installed in the low-power battery powered RTU measurement and control terminal. Due to the limited power of the battery pack, the terminal can only support data regular reporting and change reporting. The terminal frequently collects pressure and other data and compares them with the set upper and lower limit values. When the data exceeds the limit, it will be reported immediately. When the data does not exceed the limit, it will be stored and reported together until the set reporting time. A set of 4-cell high-energy lithium batteries can generally support the normal operation of the equipment for 1-2 years.

The terminal equipment is in the sleep state at ordinary times and wakes up only when reporting data. At ordinary times, it does not support the active inquiry of the dispatching center.

2. Setup and maintenance

The equipment maintenance personnel of the water department can install, set and maintain the low-power battery powered RTU measurement and control terminal through simple training. This not only facilitates users, but also greatly improves the popularity of products. Low power battery powered GPRS RTU measurement and control terminal adopts three setting modes: field key setting, field computer setting and remote setting of dispatching center.

Ordinary equipment maintenance personnel can use terminal keys to set or modify parameters such as measuring point number, acquisition time interval, transmission time interval, pressure transmitter range, water meter magnification, serial port rate, etc.

Relevant trained technicians can remotely set and modify more terminal equipment parameters in the dispatching center, and can also remotely upgrade the software of on-site terminal equipment.

conclusion

The low-power battery powered RTU measurement and control terminal has been used by many water companies in Liaoning, Hebei, Beijing, Shandong and other places for a long time. It is believed that the design of the function, power consumption, waterproof and maintenance of the product is based on the reality of field application, solves many practical problems and has great promotion value.

Manager Wang

Manager Wang

OfficialAccounts

OfficialAccounts